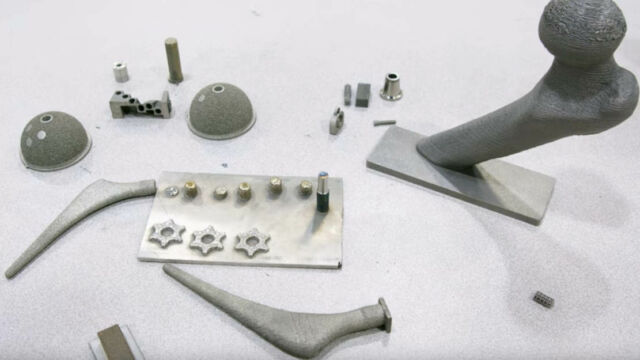

WSU researchers used simulated crushed Martian rock and metal to make strong, durable parts in a 3D printing process that one day could be used on Mars.

If humans go to Mars, we won’t be able to bring everything with us. We will have to make some things there.

A little Martian dust appears to go a long way. A small amount of simulated crushed Martian rock mixed with a titanium alloy made a stronger, high-performance material in a 3D‑printing process that one day could be used on Mars to make tools or rocket parts.

The parts were made by Washington State University researchers with as little as 5% up to 100% Martian regolith, a black powdery substance meant to mimic the rocky, inorganic material found on the surface of the red planet.

While the parts with 5% Martian regolith were strong, the 100% regolith parts proved brittle and cracked easily. Still, even high-Martian content materials would be useful in making coatings to protect equipment from rust or radiation damage, said Amit Bandyopadhyay, corresponding author on the study published in the International Journal of Applied Ceramic Technology.

“In space, 3D printing is something that has to happen if we want to think of a manned mission because we really cannot carry everything from here,” said Bandyopadhyay, a professor in WSU’s School of Mechanical and Materials Engineering. “And if we forgot something, we cannot come back to get it.”

source Washington State University

Leave A Comment