The Freightliner hybrid SuperTruck‘s features innovative energy management-optimized hardware and software, it’s actually 115% better than the average big trucks on the road now.

Images credit Daimler Trucks North America

The Freightliner SuperTruck, by Daimler group, basic shape was born as a 3D computer model, which was carefully honed by aerodynamicists using digital wind. After six months of analysis and countless computer simulations, every curve and surface optimized to reduce drag and boost efficiency.

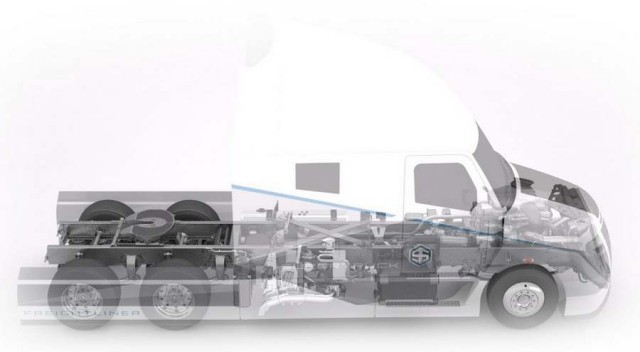

The Freightliner SuperTruck’s chassis may look like an ordinary one, but features an all-new powertrain, cab and exterior and the chassis was redesigned from the ground up as well.

Solar panels run the length of the top of the trailer, helping to charge the hybrid battery, powering the eHVAC system, that on a sunny day can provide enough energy to run the AC system continuously without the engine running.

Part of the SuperTruck challenge pushed manufacturers to create an engine that delivers 50% brake thermal efficiency. The Freightliner SuperTruck engine hit the mark, in the form of a downsized and downsped 10.7-liter engine, a hybrid system, a Waste Heat Recovery (WHR) system, along with a host of other upgrades. From top to bottom, the Freightliner SuperTruck is an extreme example of what can be done in the pursuit of peak efficiency.

source Freightliner SuperTruck

Leave A Comment