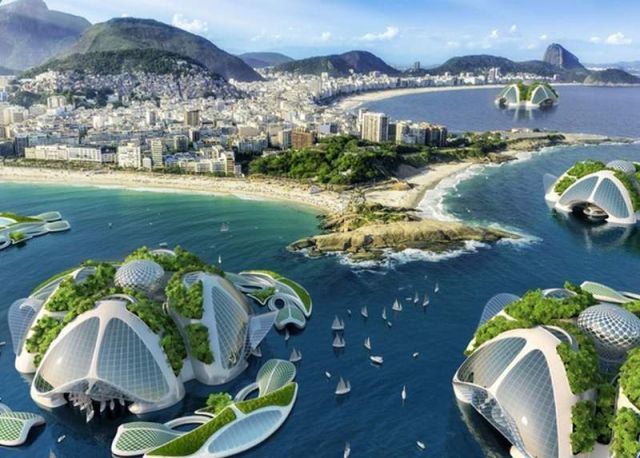

A multi-use Oceanscraper floating colony concept, designed to be 3D printed from the seventh continent’s garbage.

Vincent Callebaut Architectures has envisions Oceanscraper floating villages, 3D printed from recycled materials, algae and plastic waste, for “climate change refugees.”.

Images credit Vincent Callebaut Architectures

This futuristic project is sited off the shore of Rio de Janeiro, like a small city, is offering sustainable habitat for 10,000 housing units, office, gardens, sea farms and much more.

LOCATION : The 5 Ocean Gyres and Rio de Janeiro, Brazil

HOUSING SURFACE AREA : 1.375.000 m²

DIMENSIONS : 500 meters width, 1000 meters depth, 250 floors (1/4 for permaculture and agro-ecology)

PROGRAM : 10 000 housing (between 25 & 250m²), fab labs, offices, co-working spaces, workshops, scientific basis, sea farms, organic agriculture, community orchards and food gardens, phytopurification lagoons, coral gardens, etc.

BUILDING COST : 1950 euros/m²

STATUS : Research & Development

ENGLISH TRANSLATION : Marianne O’Donnel

Aequorea of Rio de Janeiro, December 24th, 2065

Hi People of the Land,

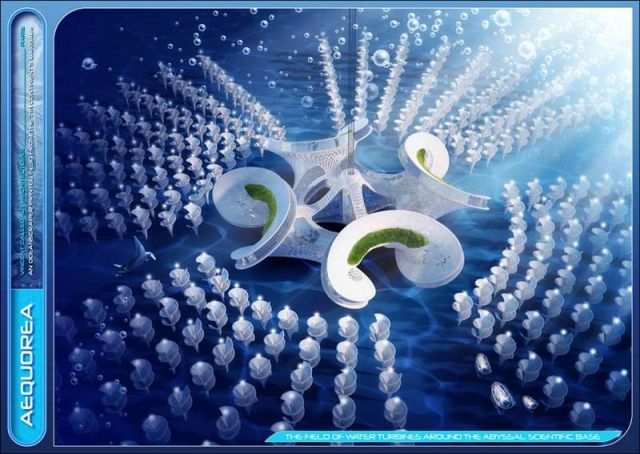

My name is Océane. I’m 15 years old. I’m an aquanaut teen. I was born in immersion in 2050 in an underwater farm called “Aequorea” off the coast of Rio de Janeiro. Bio-inspired, the farm draws its name from a bioluminescent, light-emitting jellyfish characterized by its articulated, webbed tentacles. These tentacles enable it to swim and ensure its stability, while producing its own energy.

My grandparents are oceanographers and architects. For the past 50 years, they’ve been participating in the collaborative construction of Aequorea. It’s a genuine underwater village printed in 3D from algoplast, a composite material they invented that mixes algae with garbage from the 7th continent. You know, the 7th continent? That infamous soup of plastics formed at the beginning of the century in the heart of the five main ocean gyres, where the Coriolis effect causes the currents to swirl.

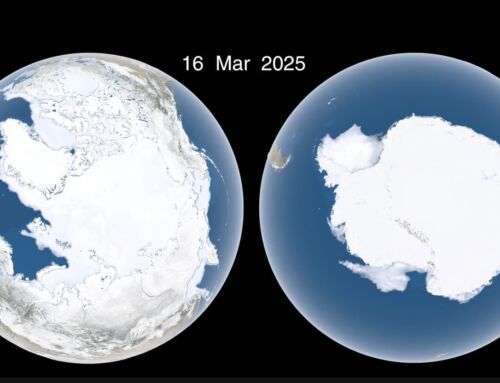

In the 20th Century, on Earth, every human being was producing up to ten times their weight in garbage annually. Two hundred and sixty-nine million tons of plastic waste with a life expectancy of a thousand years were thus produced every single year, and more than 10% of it were ending up in the oceans.

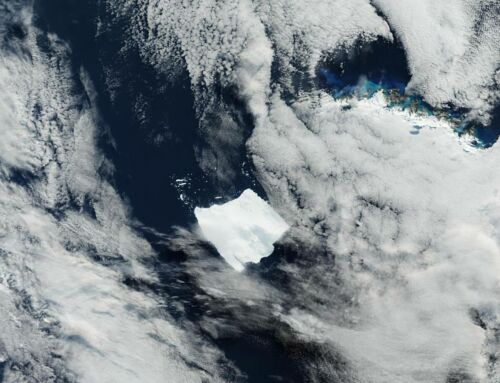

My grandmother explained to me that, geopolitically, the 7th continent didn’t belong to any state. It was indeed located in international waters. Through negligence, no one wanted to commit to cleaning those 27 million tons of plastic waste trapped by the sea currents in the heart of their vortex. The oceans, which cover 71% of the surface of our blue planet, had become the dumping ground of humanity, she told me.

Well, my grandparents, together with a community of scientists, decided to extract value from this disgusting soup of petroleum-based waste by recycling it. They formed an NGO to defend an ethical approach to the oceans. Aboard their weird ships inspired from the Klein bottle, they tirelessly sorted and crushed into granules bottles, cans, bags and other types of packaging. They filtered the microparticles suspended at depths of 10 to 30 meters (30 to 100 feet). Inside moon-crescent-shaped floating workshops and fab labs, they mixed this raw material with an emulsion of gelling algae, to extrude it in the form of eco-friendly filaments. Those reels of eco-friendly filaments were then used by 3D architectural printers to reinvent naval construction. As soon as 2015, they began the repurposing of plastic waste dumped by the People of the Land into impervious, durable materials.

via archdaily

Leave A Comment