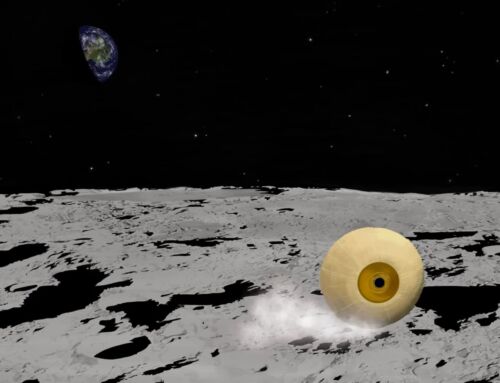

Moonrise laser system brings 3D-printing to the moon, by melting moon dust with the laser.

The Moon, first destination on the way to other planets, enormously important for space research: With the ambitious Moonrise project, the Laser Zentrum Hannover e.V. (LZH) and the Institute of Space Systems (IRAS) of the Technical University of Braunschweig are aiming at melting moon dust with a laser in order to make it usable as building material.

International space agencies and companies are not only planning to further explore, but to colonize space. The moon is of great importance as a research station and starting point for further expeditions. However, the cost of flights and transports to the moon are enormous – a kilogram of loading capacity costs approximately 700,000 Euros. Therefore, infrastructure, components and devices, etc., would at best be manufactured directly on the Earth’s satellite.

This is where the Moonrise technology comes in:

“We want to bring a laser system to the moon, which is supposed to melt moon dust, the so-called regolith. We would thus take the first step to take Additive Manufacturing, that is 3D printing, to the moon, “explains Niklas Gerdes from the LZH. In that way, the scientists from IRAS and LZH want to prove the following: A laser system that weighs no more than three kilograms and has the volume of a large juice package can melt down local raw materials on the moon and convert them into versatile structures later.

The opportunity to fly their Moonrise technology to the moon in 2021 with the first moon mission of the Berlin-based New-Space company PTScientists offers the researchers from Lower Saxony the unique opportunity to test their pioneering technology under real conditions.

source LZH

Leave A Comment