Scientists invented a method to shrink objects to the nanoscale, producing 3-D structures one thousandth the size of the originals.

MIT researchers have invented a way to fabricate nanoscale 3-D objects of nearly any shape. They can also pattern the objects with a variety of useful materials, including metals, quantum dots, and DNA.

Using the new technique, the researchers can create any shape and structure they want by patterning a polymer scaffold with a laser. After attaching other useful materials to the scaffold, they shrink it, generating structures one thousandth the volume of the original.

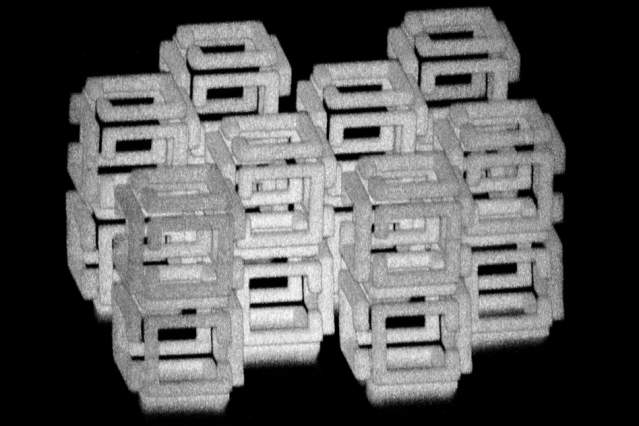

Above image, engineers have devised a way to create 3-D nanoscale objects by patterning a larger structure with a laser and then shrinking it. This image shows a complex structure prior to shrinking. Creditr Daniel Oran

These tiny structures could have applications in many fields, from optics to medicine to robotics, the researchers say. The technique uses equipment that many biology and materials science labs already have, making it widely accessible for researchers who want to try it.

Edward Boyden, the Y. Eva Tan Professor in Neurotechnology and an associate professor of biological engineering and of brain and cognitive sciences at MIT, said:

“It’s a way of putting nearly any kind of material into a 3-D pattern with nanoscale precision.”

Boyden, who is also a member of MIT’s Media Lab, McGovern Institute for Brain Research, and Koch Institute for Integrative Cancer Research, is one of the senior authors of the paper, which appears in the Dec. 13 issue of Science. The other senior author is Adam Marblestone, a Media Lab research affiliate, and the paper’s lead authors are graduate students Daniel Oran and Samuel Rodriques.

Existing techniques for creating nanostructures are limited in what they can accomplish. Etching patterns onto a surface with light can produce 2-D nanostructures but doesn’t work for 3-D structures. It is possible to make 3-D nanostructures by gradually adding layers on top of each other, but this process is slow and challenging. And, while methods exist that can directly 3-D print nanoscale objects, they are restricted to specialized materials like polymers and plastics, which lack the functional properties necessary for many applications. Furthermore, they can only generate self-supporting structures. (The technique can yield a solid pyramid, for example, but not a linked chain or a hollow sphere.)

source MIT

Leave A Comment