NASA 3D prints complex metallic “space fabric,” to be used to shield a spacecraft from meteorites and more.

The prototype fabrics that fashion designer in Spain Polit Casillas and colleagues have created, could also eventually be used for astronaut spacesuits, or for capturing objects on the surface of another planet.

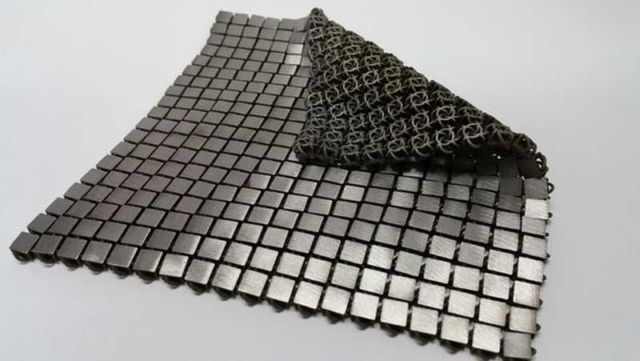

Above, the metallic “space fabric” that was created using 3-D printing techniques that allow different functionality to be integrated into each side of the material. Credit: NASA/JPL-Caltech

One potential use might be for an icy moon like Jupiter’s Europa, where these fabrics could insulate the spacecraft. At the same time, this flexible material could fold over uneven terrain, creating “feet” that won’t melt the ice under them.

‘Space Fabric’ look like chain mail, with small silver squares strung together. But these fabrics were not sewn by hand; instead, they were “printed,” created in one piece with advanced technologies.

A technique called additive manufacturing, otherwise known as 3-D printing on an industrial scale, is necessary to make such fabrics. Unlike traditional manufacturing techniques, in which parts are welded together, additive manufacturing deposits material in layers to build up the desired object. This reduces the cost and increases the ability to create unique materials.

Polit Casillas, said:

“We call it ‘4-D printing’ because we can print both the geometry and the function of these materials. If 20th Century manufacturing was driven by mass production, then this is the mass production of functions.”

source NASA

Leave A Comment