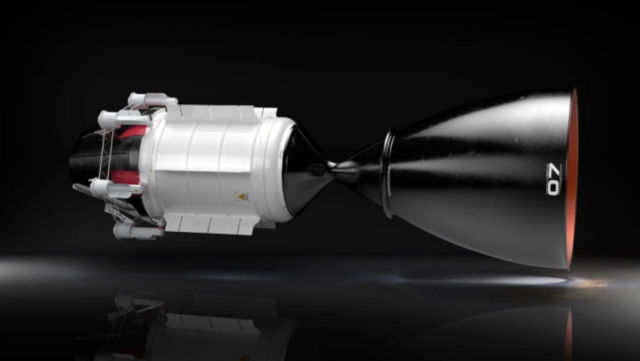

New propulsion concept providing advanced nuclear thermal design to NASA, to facilitate rapid transportation to the Moon and Mars.

Ultra Safe Nuclear Technologies has delivered a design concept to NASA as part of a study on nuclear thermal propulsion (NTP) flight demonstration. NTP technology provides unprecedented high-impulse thrust performance for deep space missions such as crewed missions to the moon and Mars. The NASA-sponsored study, managed by Analytical Mechanics Associates (AMA), explored NTP concepts and designs enabling deep space travel.

To go to Mars, that is about 40 million miles from Earth, will take seven months. USNC-Tech’s nuclear engine can send a spaceship in three months.

“We want to lead the effort to open new frontiers in space, and do it quickly and safely,” said Dr. Michael Eades, principal engineer at USNC-Tech. “Our engine maximizes the use of proven technology, eliminates failure modes of previous NTP concepts, and has a specific impulse more than twice that of chemical systems.”

“Key to USNC-Tech’s design is a conscious overlap between terrestrial and space reactor technologies,” explained Dr. Paolo Venneri, CEO of USNC-Tech. “This allows us to leverage the advancements in nuclear technology and infrastructure from terrestrial systems and apply them to our space reactors.” A prime example of this is the nuclear fuel at the core of the USNC-Tech NTP concept.

The USNC-Tech NTP concept uses a specialized variation of USNC’s FCM™ fuel, featuring high-assay low-enriched Uranium (HALEU) ZrC-encapsulated fuel particles. This variation enables high-temperature operation while maintaining the integrity of the fuel. FCM™ fuel is extremely rugged, enabling a new family of inherently safe space-optimized reactor designs that ensure astronaut safety and environmental protection. Using low quantities of HALEU, this unique NTP concept delivers high thrust and specific impulse previously only achievable through high-enriched uranium. Furthermore, FCM™ fuel leverages pre-existing supply chains and manufacturing facilities used by terrestrial nuclear reactor developers, reducing production risks and enabling sustainable industry involvement.

It was a great design.