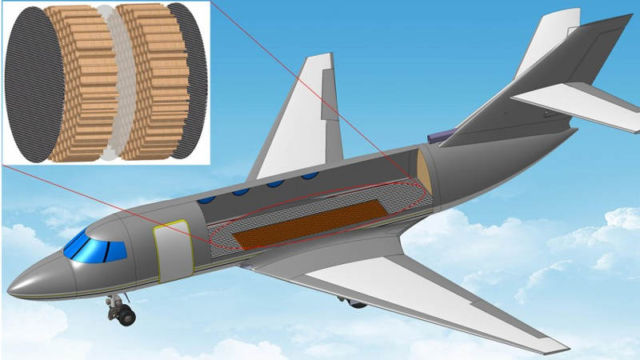

A new lightweight membrane that will definitely reduce aircraft noise, when inserted into the honeycomb structures used in the design, unveiled.

Image credit Yun Jing

Researchers from North Carolina State University and MIT have developed a thin, lightweight membrane that covers one side of the honeycomb structure, like the skin of a drum. When sound waves hit the membrane, they bounce off and not passing through.

The strong honeycomb structures are very bad at blocking low-frequency noise – like the noise of an plane engine. And adding insulation materials to limit the noise would add significant weight to the aircraft, making it much less fuel efficient.

NC State and MIT researchers have developed a possible solution.

Yun Jing, an assistant professor of mechanical and aerospace engineering at NC State and senior author of a paper describing the work, said:

“This design is promising for making structures that are strong, lightweight, and sound-proof.

It’s particularly effective against low-frequency noise. At low frequencies – sounds below 500 Hertz – the honeycomb panel with the membrane blocks 100 to 1,000 times more sound energy than the panel without a membrane.”

The membrane is made of rubber that is about 0.25 millimeters thick, and adds about 6 percent to the overall weight of the honeycomb panel.

Ni Sui, a Ph.D. student in Jing’s lab and lead author of the paper, said:

“The membrane is relatively inexpensive to produce, and can be made of any material that does not impact the structural integrity of the honeycomb panel. It could make flying much more pleasant for passengers –particularly in helicopters.”

Leave A Comment