Foster + Partners has been shortlisted as one of the finalists, among 30 shortlisted, for the 3D printed habitat on the red planet, in NASA-backed Mars Habitat Competition.

Images credit Foster + Partners

Foster + Partners unveiled their entry for the 3D printed habitat challenge organized by America Makes and NASA, built by an array of pre-programmed, autonomous robots.

The design outlines plans for a settlement on Mars constructed by an array of pre-programmed, semi-autonomous robots.

The project will be ready prior to the eventual arrival of the astronauts.

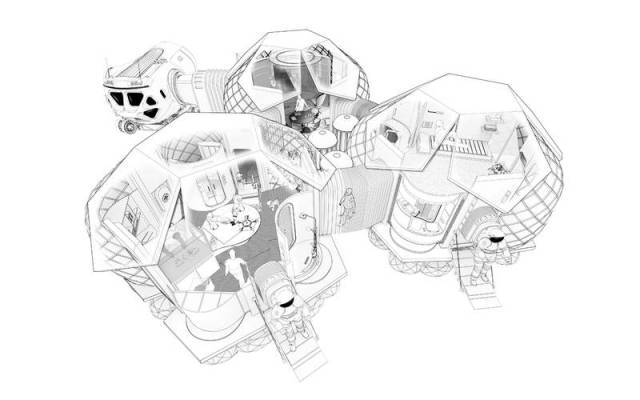

The design of the habitat – carried out in collaboration with industrial and academic partners – envisions a robust 3D-printed dwelling for up to four astronauts constructed using regolith – the loose soil and rocks found on the surface of Mars.

The proposal considers multiple aspects of the project from delivery and deployment to construction and operations. The habitat will be delivered in two stages prior to the arrival of the astronauts. First, the semi-autonomous robots select the site and dig a 1.5 metre deep crater, followed by a second delivery of the inflatable modules which sit within the crater to form the core of the settlement. Given the vast distance from the Earth and the ensuing communication delays, the deployment and construction is designed to take place with minimal human input, relying on rules and objectives rather than closely defined instructions. This makes the system more adaptive to change and unexpected challenges – a strong possibility for a mission of this scale.

Three different kinds of robots are parachuted to the surface of Mars, each performing a specialised task within the large-scale Regolith Additive Construction (RAC) process. The larger ‘Diggers’ create the crater by excavating the regolith, which the medium-sized ‘Transporters’ then move into position over the inflatable habitat modules layer by layer. The loose Martian soil is then fused using microwaves around the modules using the same principles involved in 3D-printing by several small ‘Melters’.

via Dezeen

source Foster + Partners

Leave A Comment